|

Getting old Lizzie

going is one thing, getting her stopped is another! These Rocky

Mountain brakes are almost a must when you have a Ruckstell or

overdrive. Hooks up to the regular brake pedal, and uses the

rear wheels to stop instead of the transmission.

The installation instructions

can be downloaded

here.

The installation instructions

can be downloaded

here.

Be sure to read

the differences between the two types

here. Be sure to read

the differences between the two types

here.

Click here to jump

straight to the step

by step guide.

Click here to jump

straight to the step

by step guide.

DISCLAIMER:

First let us state that the images and descriptions shown here

do not preclude reading and understanding all the directions

that come with the Rocky Mountain Brake kit. You, and you alone

are responsible for the installation of anything on your 90+

year old car. Please read the instructions that come with the

kit. We share this information to aid in your understanding. By

no means is this information intended to solely instruct the car

owner or mechanic to install this system.

1926

-1927 installation also ?t? trucks

Correct rear axle for the above years has an 11? brake drum and

housing (ex- ception being ?t? ?t? truck worm drive) and do not

interchange with the 1909- 25 8? rear axle assembly. Hassler

shocks can not be used with the additional brakes. Before

starting, check to see if the stock drum is close to the backing

plate. Any large gap here (too many shims, incorrect parts) will

show up later as brake bands will not line up on drums. This

assembly is designed for ?t?s as ford manufactured. Any modified

frames, as with speedsters, you will have to make your own

alterations. Start by removing rear wheels.

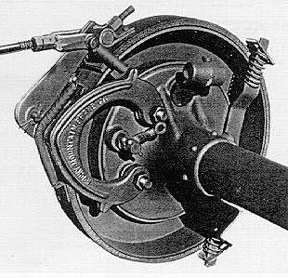

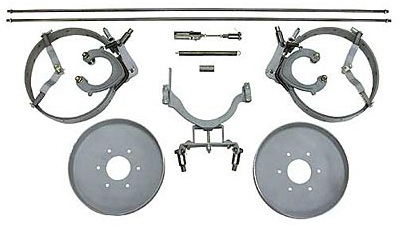

Brake assembly installation

Bands are tagged left side up-right side up (left side is

drivers side -u.s.a.). Start by removing the 2 bolts from radius

rods. Using bolts supplied, place the front bolts thru the wheel

side of the backing plate and radius rod, keep- ing radius rods

in same location against backing plate. Do not attempt to place

casting between backing plate and radius rods! The 2 rear most

1/4? riv- ets must be removed for the rear support brackets

using 1/4? bolts supplied (not required on ?t? ?t? one 5/8?

bolt) .now place casting and band assembly onto bolts. The rear

spring brackets, the shortest goes on first to the top, then the

longer faces to the bottom. Leave final nuts off these for now

(?t? ?t? brackets are installed as assembled). Place wheel on

axle without axle key. Run nut up to hub and slip cotter pin in

place. This way you may spin wheel without turning the whole

gear assembly. Check for any parts that may be dragging against

drum because of worn axle surfaces or hubs caused by bro- ken

axle keys. Over time, wheels may go on further than originally.

You may solve this by grinding face of offending part slightly

or add an axle shim. Install final nut on rear support brackets

and adjust top bracket so there is space between bracket and

band tab towards rear of car. Bottom bracket

Is adjusted with space between bracket and band tab towards

front of car. The reason for this is to allow band to travel

forward with the rotation of the wheels which is where the self

energizing feature is obtained.

Adjusting band

Run down the top major adjustment nut until lining is tight

against the drum. Now adjust the nuts that are below on the

threaded 6 1/2? bolt to give the spring about 1? in length. Back

off the top adjustment nut so the wheel now will spin freely

with approximately 20 thousands clearance. The band and lining

will conform after driven a few miles and should be re-adjusted

for a more precise adjustment, but allowing for drum expansion.

Remove the wheel and replace the axle key. When doing this, be

sure the axle key does not slide further up in the keyway,

thereby not allowing the wheel to go to it?s seated position!

You can center punch on each side of the keyway to hold it in

place.

Installing wheel and cotter pin

Check all the bolts for tightness and spacing on the rear spring

loaded brack- ets. Remember, the left band rotates

counter-clockwise, the right band rotates clockwise. Do not

attempt to burn in the lining. Stopping easy to break them in

will assure years of quality braking. Always replace the axle

seals whenever you have your wheels off. Lining is costly!

Remove the pedal by taking out the 6 bolts in the hogs head.

(trans cover) place rags in all the spaces in the openings

around the drums. Tie wire around the brake band ears pushing

down on the ped- al to get the wire very tight. Remove the nut

from the shaft and then the pedal. It helps to back off the

reverse nut when replacing the brake pedal. Adjust the nut on

the band so the pedal will be about 2? from the floor board when

pressed tight. This will allow the use of the rear brakes and,

with a full pressure of the

Pedal, will engage the band brake. Also, above assumes the

welding has been com- pleted on the bottom of the pedal with the

extension supplied. (unless the option- al pedal has been

purchased with all required items cast in with the new shaft).

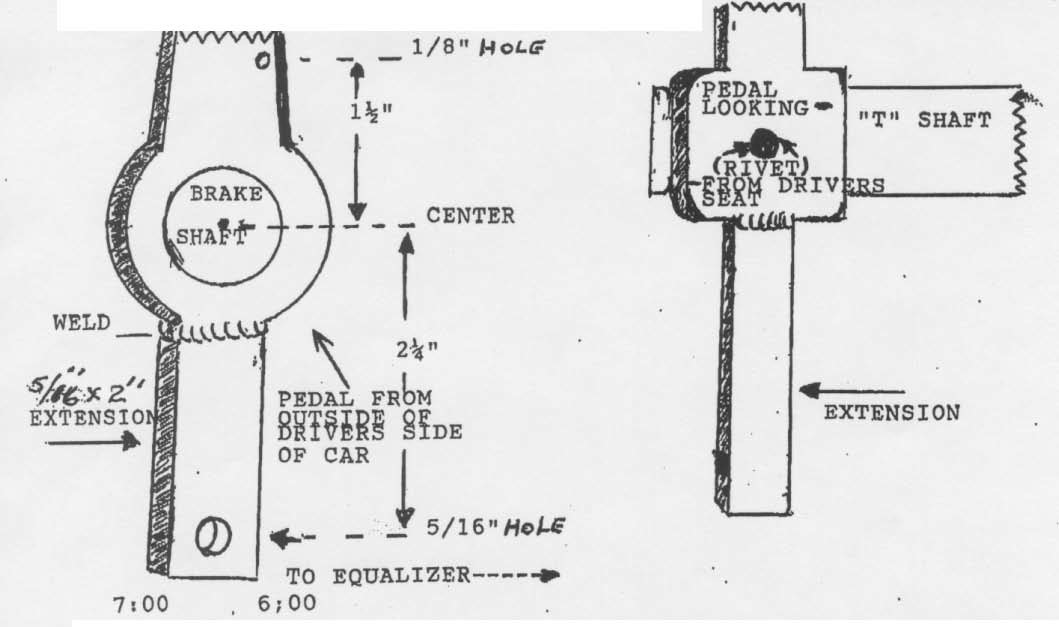

Pedal welding

The extension is to be arc welded to the bottom of the pedal in

line with the rivet and between 6 and 7 o?clock. It may be

required to remove the starter cover and/ or bendix to replace

the pedal assembly.

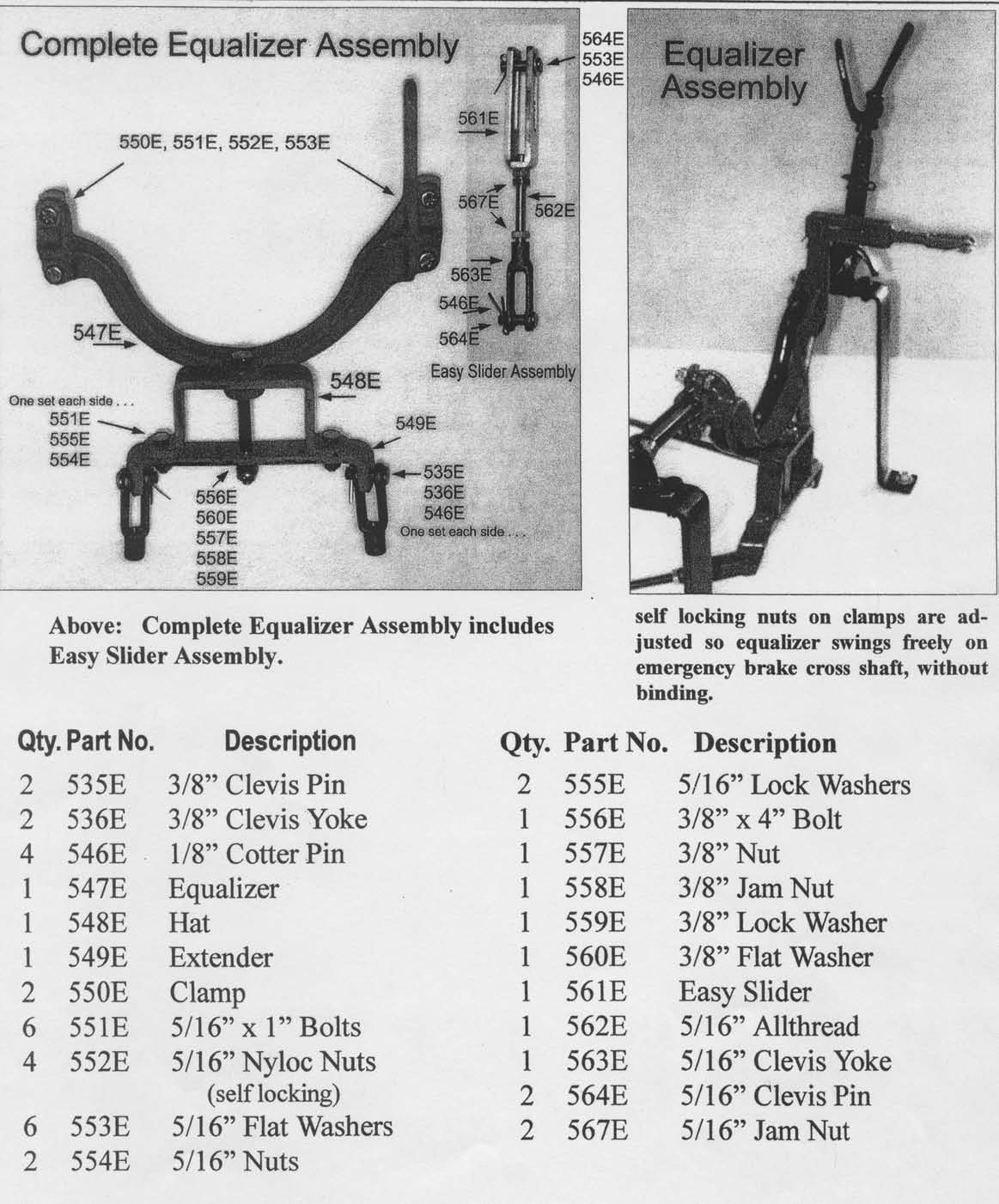

Equalizer assembly

New design sliding clevis attaches to the arm of the eouallzer.

Hang the equaliz- er in front of the parking brake cross shaft

so it just swings freely with the self- locking nuts. With the

bottom portion of the equalizer more inclined to the rear of the

car, adjust the pedal linkage so the pin in the sliding clevis

starts to move the equalizer arm. Hook the spring supplied to

the pedal and to the radius rod junction which is where the

radius rods meet on the drive shaft behind the uni- versal

joint.

Adjusting brake rods

Bending may be required on some models (note! Do not support

rods or bend near threads. Damage may occur) .adjust to take up

play between brake arms and equalizer. It is best to remove

stock rods while adjusting and then replacing. Check to see if

equalizer assembly hits oil pan with pressure applied. If so,

shorten rods. The following is to clarify the welding and

drilling of brake pedal.

Measurements are from center of brake shaft. From center down to

extension

2 1/4? drill 5/16ths hole. From center up 1 1/2?, drill a-1/8th

hole near edge for pedal spring

Final notes: brakes do not self

energize in reverse as with some modern cars. Have you ever

backed up with the brake on only to find out to go forward the

emer- gency brake was on ? Also, large amounts of water will

cause brake fade on any brake system. Exercise caution under

these conditions. Riding pedal a short dis- tance helps return

braking.

Rocky mountain brake co ., inc. Assumes no responsibility for

the installation or use of rocky mountain brakes. There is no

expressed or implied warranty of fitness for a particular

purpose. Purchaser understands this product is intended for use

in addition to the standard original brake system.

Rocky Mountain Brake co., inc.

Additional information

Do?s and Don'ts

Our product is manufactured with the finest materials available.

With care, your new braking system will last many years. We

recommend the following maintenance procedures.

Do?s

Keep all mechanical moving parts lubricated. On the 1926-27 and

?t t?, clean brake drums of any paint , rust or any other

foreign matter. If you find your equal- izer yoke assembly hits

the engine pan, you have not made your adjustment of the

emergency brake correctly .bring lever back for the pawl to just

touch the clutch adjustment bolt. Brake pedal clevises can now

be adjusted with the foot pedal that is in it?s completely

seated position. Install brake rods to equalizer

And brake arms. Recommended clearance between lining and drums

is at least .020 (twenty thousandths), cold. A feeler gauge is a

good tool for this, if available. Remember heat expands drums

which means lining actually will become closer when hot .

Mechanical brakes, as in days of old, are susceptible to fade

out when large amounts of water are encountered. To overcome

this, ride brake pedal a short dis- tance to dry out .

For the first 100 miles, allow lining to ?break in? stopping

with slight pedal pres- sure. Burning them in will cause lining

to glaze and poor stopping will occur.

Don?ts

Don?t allow paint to be sprayed on lining or lining contact

surface of brake drums. Use masking tape to protect these areas

when painting. The small amount of primer on the 1909-25 drums

is insignificant. Don?t install your new brakes if your axle

seals show any sign of leakage. It is best to replace them at

this time.

Rocky Mountain Brakes:

A Step

By Step guide...

Written by R. Peterson

The car used in

the following demo is a 1917 torpedo runabout, a car that has

been in the family since it was purchased from the original

owner in 1951. The car gained a set of Hayes wire wheels in the

1950?s, and the Ruckstell axle was installed in the 1970?s. The

car has now been in the family for 66 years, and we want it to

be safe for future generations.

Before starting

the installation we painted all the parts black and read the

installation instructions carefully.

The first step is

to remove a rear wheel so that the brakes can be added. We

jacked the car up, installed a jack stand, and pulled the left

rear wheel. The Hassler shocks on the rear axle will not work

with the Rocky Mountain brakes so they will have to be removed.

The Hassler parts

removed, we can continue with installation.

Our car has Hayes

wire wheels, a popular and attractive period accessory. The

Hayes rear hubs have a special, smaller diameter bolt pattern

holding the parking brake drum to the wheel. We will have to

drill the Rocky Mountain brake drums to match.

The Hayes brake

drum has both Ford and Hayes bolt patterns. This allows us to

bolt the Hayes drum to the Rocky Mountain brake drum to properly

align the two. We drill the six 3/8″ diameter holes on a drill

press using cutting oil and low speed. The Ford brake drum is

placed inside the Rocky Mountain brake drum. The bolts are

cleaned in MEK, dried, and then green semi permanent thread

locking Permatex compound is applied to the bolts before the

drums are secured to the wheel.

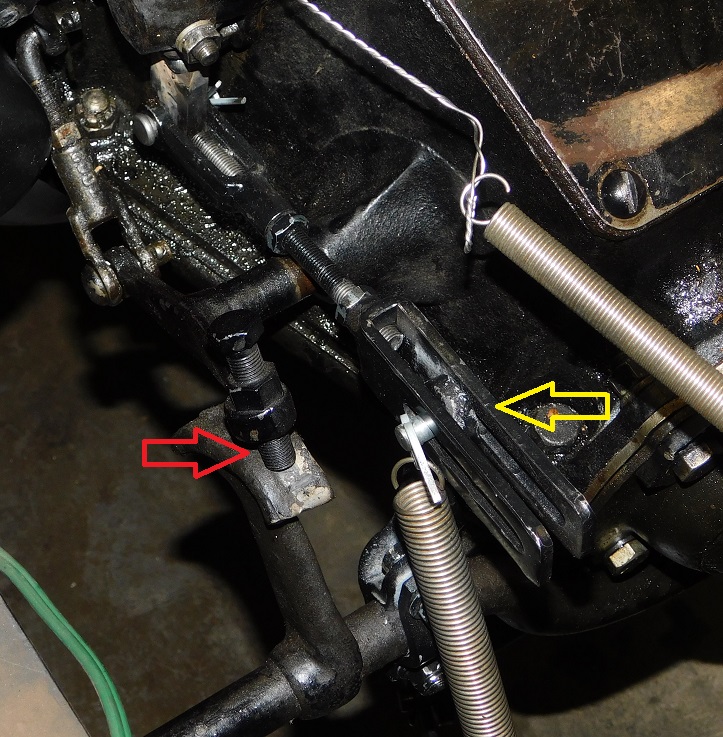

In the photo above

a yellow arrow points at an axle shim that is needed to

compensate for the additional thickness of the added Rocky

Mountain brake drum. The shim is .020″ thick, it moves the axle

.090″ out from center. The shims are not included in the RM

Brake kit, you must purchase them separately or fabricate them

yourself. The Rocky Mountain brake parts are assembled per the

instructions using the new hardware supplied in the kit. The

rear wheels are installed and the axle nuts tightened and new

cotter pins installed.

Next we removed the floor boards and the transmission door so

that the brake pedal could be removed. Our 1917 had a starter

added, so the bendix cover had to be removed in order that the

brake pedal could be removed and replaced.

There is a piece

of steel plate included in the kit. You must drill a 5/16″ hole

in the plate to accept the brake clevis. The plate must be

beveled on the end to be welded in order to allow a larger

surface area for the weld, making it stronger.. A flat spot is

ground on the bottom of the pedal so the plate will have full

contact in the area to be welded. I took my pedal over to my

friend Nolan?s house. Nolan skillfully used his DC Arc welder to

put a nice fat bead on both sides of the plate.

Another view of

the plate installed on the bottom of the pedal. The pedal

assembly can be painted if you wish, but given the environment

it lives in there is little reason to believe it would ever get

rusty.

The brake rods and clevis assemblies from the Rocky Mountain kit

were assembled. The equalizing assembly is installed on the

forward side of the Model T parking brake shaft. All the

clevises are hooked up with no cotter pins for now.

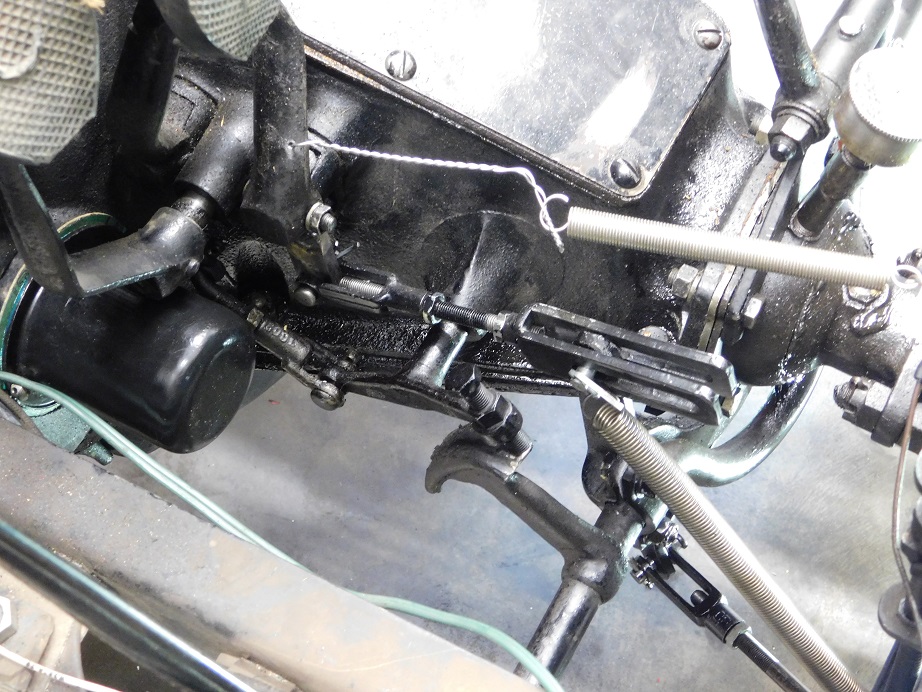

Above, an overview

of the installed brake pedal and equalizer with the brake lever

as far forward as it can go. It is important to properly adjust

the Ford parking brake before connecting the Rocky Mountain

Rods. The Ford parking brake lever when fully forward should

leave the brake cross shaft clutch arm just barely clear of the

clutch adjustment bolt. When the parking brake is applied with

the Rocky Mountain brakes disconnected the Ford brake lever

should be vertical, not all the way back against the seat.

In the above photo

we see just a little clearance at the sliding clevis pin (yellow

arrow). The Ford brake pedal is adjusted so that when applied

the brake pedal is fully engaged and will stop the car with the

pedal about 1″ above the floor board. Test drive the car with

the Rocky Mountain brakes completely disconnected, make sure

that the Ford brake functions properly when going forward and

reverse. In this photo the parking brake lever is all the way

forward, note the (red arrow) clutch adjustment bolt just

clearing the brake cam.

Above, another

view showing the controls in the driving position with brakes

released.

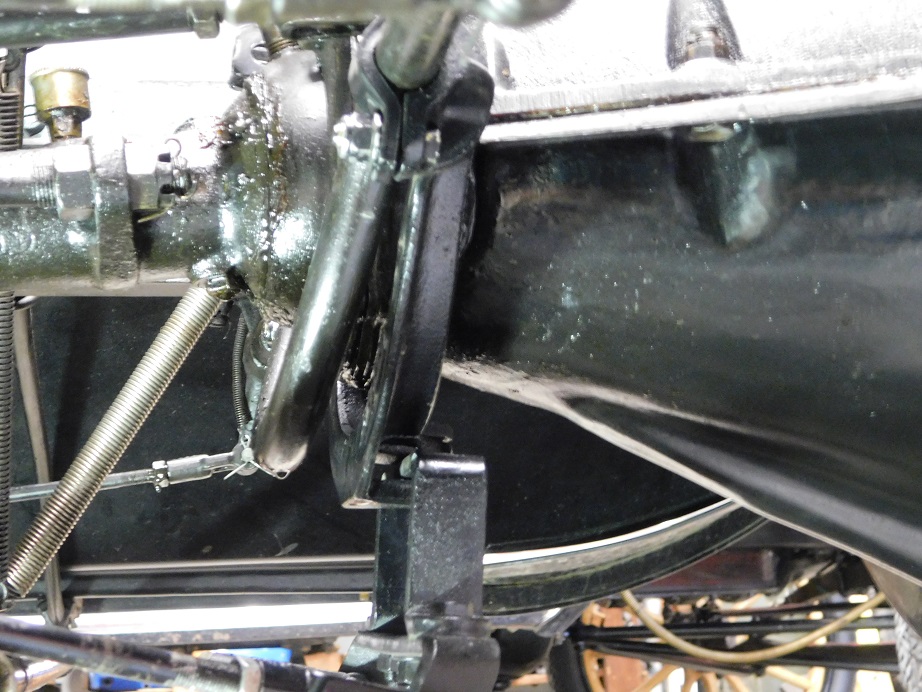

Above, the view of

the equalizer under the car with the brakes released and

properly adjusted.

Above, with the

brake lever applied the equalizer assembly is pushed forward by

the Ford brake lever shaft. It moves the brake rods

approximately 1/2" with everything adjusted properly.

Once you are happy with all of the brake adjustments double

check all of your work. Make sure all the bolts and nuts on the

brakes at the rear wheels are tight and install all the cotter

pins, but don?t bend them fully quite yet. Take the car on a

test drive for a few minutes. Make sure the car will stop while

backing up. Make sure the brakes hold well on a hill, going

backwards and forwards. Some additional fiddling and adjusting

will e necessary, I played with adjustments for nearly half a

day before becoming satisfied. When you feel that all is right

then get the car up to cruising speed, with no traffic around

and dry streets. Perform a few panic stops to see how it feels.

The car should stop without pulling to one side or the other.

One thing that I found after the first test drive was a

horrendous oil leak. When I removed the brake pedal I had

removed the starter bendix cover to get clearance. It was

removed again to try and figure out why we had such a big leak.

With it all apart again we were surprised to find the gasket

appeared to be perfect and no apparent problems. Everything was

cleaned with lacquer thinner and gasket sealant was used on the

next attempt. There were no leaks from the bendix cover after

that.

|