|

The Ford

Model T

|

|

Manufacturer |

Ford Motor Company |

|

Production |

19081927 |

|

Assembly |

Detroit, US;

Highland Park, US;

Minneapolis, US

Buenos Aires, Argentina;

Geelong, Australia;

Sγo Bernardo do Campo, Brazil;

Toronto, Ontario, Canada;

Walkerville, Ontario;

Copenhagen, Denmark;

Manchester, England;

Berlin, Germany;

Cork, Ireland |

|

Predecessor |

Ford Model S |

|

Successor |

Ford Model A |

|

Class |

Full-size Ford, economy car |

|

Body style |

2-door touring (190911)

3-door touring (19121925)

4-door touring (19261927)

no door roadster (190911)

1-door roadster(19121925)

2-door roadster (19261927)

roadster pickup (19251927)

2-door coupι (19091912, 19171927)

2-door Coupelet (191517)

Town car (19091918)

C-cab wagon (1912)

2-(Center)door sedan (19151923)

2-door sedan (19241927)

4-door sedan (19231927)

Separate chassis were available all years for independent coachbuilders |

|

Layout |

FR layout |

|

Engine |

177 C.I.D. (2.9 L) 20 hp I4 |

|

Transmission |

2-speed planetary gear |

|

Wheelbase |

99.0 in (2,515 mm) |

|

Length |

134 in (3,404 mm) |

|

Curb weight |

1,200 pounds (540 kg) |

|

Designer |

Henry Ford, Childe Harold Wills, Joseph A. Galamb and Eugene Farkas |

|

|

A major innovation brought

about by Henry Ford was the assembly line. He

realized that it would be much simpler, more practical,

and quicker if , when assembling the vehicle, the

workers could draw the various components from suitable

containers placed beside the production line, rather

than going to the various storerooms for them, which

meant they had constantly to by moving from place to

place. In this way he managed to reduce the assembly

time from 12 hours to a car coming off the line every 40

seconds.

Background

The

Ford Model T (colloquially known as the

Tin Lizzie, Flivver, T‑Model Ford, or

T) is an automobile that was produced by Henry

Ford's Ford Motor Company from September 1908 to May

1927. It is generally regarded as the first affordable

automobile, the car that opened travel to the common

middle-class American; some of this was because of

Ford's innovations, including assembly line production

instead of individual hand crafting. The Ford Model T

was named the world's most influential car of the 20th

century in an international poll.

The Model T set 1908 as the

historic year that the automobile became popular. The

first production Model T was produced on August 12, 1908

and left the factory on September 27, 1908, at the

Piquette Plant in Detroit, Michigan. On May 26, 1927,

Henry Ford watched the 15 millionth Model T Ford roll

off the assembly line at his factory in Highland Park,

Michigan.

There were several cars

produced or prototyped by Henry Ford from the founding

of the company in 1903 until the Model T came along.

Although he started with the Model A, there were not 19

production models (A through T); some were only

prototypes. The production model immediately before the

Model T was the Model S, an upgraded version of the

company's largest success to that point, the Model N.

The follow-up was the Ford Model A and not the Model U.

Company publicity said this was because the new car was

such a departure from the old that Henry wanted to start

all over again with the letter A. The Model T was the

first automobile mass produced on moving assembly lines

with completely interchangeable parts, marketed to the

middle class. Henry Ford said of the vehicle:

"I will build a car for the

great multitude. It will be large enough for the

family, but small enough for the individual to run

and care for. It will be constructed of the best

materials, by the best men to be hired, after the

simplest designs that modern engineering can devise.

But it will be so low in price that no man making a

good salary will be unable to own one and enjoy

with his family the blessing of hours of pleasure in

God's great open spaces."

Why the Model T was so important

Before the Model T, most cars cost

lots of money. Only people with lots of money could

afford them. Even Ford's cars before the Model T cost a

lot of money. The model t went for around $980. A car

built in 1903 called the Oldsmobile Curved Dash was very

easy to buy, but was a very simple and slow car that was

more like a buggy than a car.

The man who owned the company, Henry Ford, heard about

meat being packed on an assembly line, which moved meat

from worker to worker so that the meat could be cut up.

No one had ever thought to use an assembly line to put

cars together. Ford knew that if he built his cars on an

assembly line instead of one at a time like other cars,

he could make a car that anyone could afford and would

be built like cars that cost more money. He also knew

that he could pay his workers lots more money.

The Ford Model T car was designed by Henry Ford, Childe

Harolde Wills and two Hungarian men named Jσzsef Galamb

and Eugene Farkas. The Model T had a 177 cubic inch (2.9

L) four-cylinder engine producing 20 horsepower (15 kW)

for a top speed of 45 miles per hour (72 km/h). The

engine had side valves and three main bearings. Fuel

economy was 14 to 21 miles per gallon (6 to 9 km/l), an

excellent number even today.

In the the Beginning

Ford began building the Model T in

his Piquette factory on October 6, 1908 as a 1909 model.

Workers from all over the world wanted to work for Ford

because of the good pay. Workers could even save their

money for a Model T of their own. The price of the Model

T dropped over the years, making it even easier to buy.

Work began at one end of the assembly line, starting

with an empty chassis. From there, the chassis moved

slowly down the assembly line. Workers on the assembly

line added parts to the chassis. Before long, a new

Model T rolled off the other end of the line. Different

body styles were available, even a truck, or Model TT.

At first, the only color available was black. Black

paint was used because it was cheaper than other paints

and Ford was obsessed with increasing profit. As car

paint got better over the years, Ford began offering

other colors. The time it took a chassis to become a

finished car was over twelve hours when the first Model

T's were built. By the time the last Model T came off of

the line, Ford had so many auto plants it was making one

car every 40 seconds!

Even though the Model T sold for little money, Ford used

the best materials he could buy to make his car. Most

roads in the Model T's day were dirt, gravel or even

mud. That meant the Model T had to be very strong, and

it was. The wheels and tires were very tall and skinny

so that they could sink into mud roads and not get

stuck. It was also very simple.

Ford in Australia

On March 31, 1925, Ford announced that Geelong, was to

be the Australian headquarters. The first

Australian-built Ford was a Model T that came off an

improvised production line in a disused Geelong

woolstore in June 1925, while work started on a factory

in the nearby suburb of Norlane. In 1928 the factory

switched to the Model A and was followed by the Ford V8

in 1932.

In 1934 the company released the world's first coupe

utility. The inventor was Ford engineer Lewis Bandt.

During the Depression, banks would not extend credit to

farmers to purchase passenger cars- in the belief they

were unnecessary luxuries. However, they would lend

money for the purchase of "working" vehicles. The coupe

utility fulfilled the need of farmers to have a

workhorse which could also be used "to take the wife to

church on Sunday and to the market on Monday".

In 1956 the company bought a large tract of land in the

northern Melbourne suburb of Broadmeadows, and in July

1961 announced that the new Melbourne factory would

become the company headquarters.

Characteristics

The Ford Model T car was designed

by Childe Harold Wills and two Hungarian immigrants,

Joseph A. Galamb and Eugene Farkas. Henry Love, C. J.

Smith, Gus Degner and Peter E. Martin were also part of

the team. Production of the Model T began in the third

quarter of 1908. Collectors today sometimes classify

Model Ts by build years and refer to these as "model

years", thus labeling the first Model Ts as 1909 models.

This is a retroactive classification scheme; the concept

of model years as we conceive it today did not exist at

the time. The nominal model designation was "Model T",

although design revisions did occur during the car's two

decades of production.

Engine and means of starting

The

Model T had a 177-cubic-inch (2.9 L) front-mounted

inline four-cylinder en bloc engine (that is, all

four cylinders in one block, as common now, rather than

in individual castings, as common then) producing 20 hp

(15 kW) for a top speed of 4045 mph (6472 km/h). The

Model T four-cylinder side valve engine was first in the

world with a detachable head, making service like valve

jobs easier. According to Ford Motor Company, the Model

T had fuel economy on the order of 1321 mpg-US

(1625 mpg-imp; 1811

L/100 km). The engine was capable of running on petrol,

kerosene, or ethanol, although the decreasing cost of

petrol and the later introduction of Prohibition made

ethanol an impractical fuel. The

Model T had a 177-cubic-inch (2.9 L) front-mounted

inline four-cylinder en bloc engine (that is, all

four cylinders in one block, as common now, rather than

in individual castings, as common then) producing 20 hp

(15 kW) for a top speed of 4045 mph (6472 km/h). The

Model T four-cylinder side valve engine was first in the

world with a detachable head, making service like valve

jobs easier. According to Ford Motor Company, the Model

T had fuel economy on the order of 1321 mpg-US

(1625 mpg-imp; 1811

L/100 km). The engine was capable of running on petrol,

kerosene, or ethanol, although the decreasing cost of

petrol and the later introduction of Prohibition made

ethanol an impractical fuel.

A flywheel magneto was an electrical generator that

produced the high voltage necessary to produce a spark

to initiate combustion. This voltage was distributed by

the timer (analogous to a distributor in a modern

vehicle) to one of the four trembler coils, one for each

cylinder. The coil created a high voltage current,

directly connected to the spark plug in the cylinder.

Ignition timing was adjusted manually by using the spark

advance lever mounted on the steering column which

rotated the timer. A battery could be used for starting

current: at hand-cranking speed, the magneto did not

always produce sufficient current (a starting battery

was not standard equipment until sometime in 1926,

though all T's had a bat position on the coil box

switch). A certain amount of skill and experience was

required to find the optimal timing for any speed and

load. When electric headlights were introduced in 1915,

the magneto was upgraded to supply power for the lights

and horn. In keeping with the goal of ultimate

reliability and simplicity, the trembler coil and

magneto ignition system was retained even after the car

became equipped with a generator and battery for

electric starting and lighting. Most cars sold after

1919 were equipped with electric starting, which was

engaged by a small round button on the floor.

Before

starting a Model T with the hand crank, the spark had to

be manually retarded or the engine might "kick back".

The crank handle was cupped in the palm, rather than

grabbed with the thumb under the top of the handle, so

that if the engine did kick back, the rapid reverse

motion of the crank would throw the hand away from the

handle, rather than violently twisting the wrist or

breaking the thumb. Most Model T Fords had the choke

operated by a wire emerging from the bottom of the

radiator where it could be operated with the left hand.

This was used to prime the engine while cranking the

engine slowly then starting the engine with the left

hand with a rapid pull of the crank handle. The car only

had to be cranked half a turn for it to successfully

start. This "quick start" is because of the engine's

small displacement and low compression. Before

starting a Model T with the hand crank, the spark had to

be manually retarded or the engine might "kick back".

The crank handle was cupped in the palm, rather than

grabbed with the thumb under the top of the handle, so

that if the engine did kick back, the rapid reverse

motion of the crank would throw the hand away from the

handle, rather than violently twisting the wrist or

breaking the thumb. Most Model T Fords had the choke

operated by a wire emerging from the bottom of the

radiator where it could be operated with the left hand.

This was used to prime the engine while cranking the

engine slowly then starting the engine with the left

hand with a rapid pull of the crank handle. The car only

had to be cranked half a turn for it to successfully

start. This "quick start" is because of the engine's

small displacement and low compression.

The car's 10 US gal (38 l;

8 imp gal) fuel tank was mounted to the frame beneath

the front seat; one variant had the carburetor (a Holley

Model G) modified to run on ethyl alcohol, to be made at

home by the self-reliant farmer. Because Ford relied on

gravity to feed fuel to the carburetor rather than a

fuel pump, a Model T could not climb a steep hill when

the fuel level was low. The immediate solution was to

climb steep hills in reverse. In 1926, the fuel tank was

moved forward to under the cowl on most models.

Early on, the engine blocks

were to be produced by the Lakeside Foundry on St. Jean

in Detroit. Ford cancelled the deal before many were

produced.

The first few hundred Model Ts

had a water pump, but it was eliminated early in

production. Ford opted for a cheaper and more reliable

thermo-syphon system. Hot water, being less dense, would

rise to the top of the engine and up into the top of the

radiator, descending to the bottom as it cooled, and

back into the engine. This was the direction of water

flow in most cars which did have water pumps, until the

introduction of crossflow radiator designs. Many types

of water pumps were available as aftermarket

accessories.

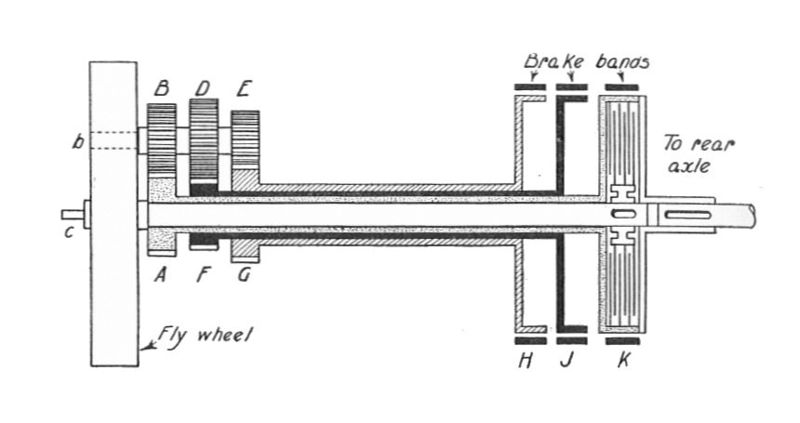

Transmission and drive train

The Model T was a rear-wheel

drive vehicle. Its transmission was a planetary gear

type billed as "three speed". In today's terms it would

be considered a two-speed, because one of the three

speeds was reverse.

The

Model T's transmission was controlled with three foot

pedals and a lever that was mounted to the road side of

the driver's seat. The throttle was controlled with a

lever on the steering wheel. The left pedal was used to

engage the gear. With the handbrake in either the mid

position or fully forward and the pedal pressed and held

forward the car entered low gear. When held in an

intermediate position the car was in neutral, a state

that could also be achieved by pulling the floor-mounted

lever to an upright position. If the lever was pushed

forward and the driver took his foot off the left pedal,

the Model T entered high gear, but only when the

handbrake lever was fully forward. The car could thus

cruise without the driver having to press any of the

pedals. There was no separate clutch pedal. The

Model T's transmission was controlled with three foot

pedals and a lever that was mounted to the road side of

the driver's seat. The throttle was controlled with a

lever on the steering wheel. The left pedal was used to

engage the gear. With the handbrake in either the mid

position or fully forward and the pedal pressed and held

forward the car entered low gear. When held in an

intermediate position the car was in neutral, a state

that could also be achieved by pulling the floor-mounted

lever to an upright position. If the lever was pushed

forward and the driver took his foot off the left pedal,

the Model T entered high gear, but only when the

handbrake lever was fully forward. The car could thus

cruise without the driver having to press any of the

pedals. There was no separate clutch pedal.

The middle pedal was used to

engage reverse gear, and the right pedal operated the

transmission brake. The floor lever also controlled the

parking brake, which was activated by pulling the lever

all the way back. This doubled as an emergency brake.

Although it was uncommon, the

drive bands could fall out of adjustment, allowing the

car to creep, particularly when cold, adding another

hazard to attempting to start the car: a person cranking

the engine could be forced backward while still holding

the crank as the car crept forward, although it was

nominally in neutral. As the car utilized a wet clutch,

this condition could also occur in cold weather, where

the thickened oil prevents the clutch discs from

slipping freely. Power reached the differential through

a single universal joint attached to a torque tube which

drove the rear axle; some models (typically trucks, but

available for cars as well) could be equipped with an

optional two-speed Ruckstell rear axle shifted by a

floor-mounted lever which provided an underdrive gear

for easier hill climbing. All gears were vanadium steel

running in an oil bath.

Suspension and wheels

Model

T suspension employed a transversely mounted

semi-elliptical spring for each of the front and rear

axles, which was a solid beam axle, not an independent

suspension, which still allowed a great deal of wheel

movement to cope with the dirt roads of the time. Model

T suspension employed a transversely mounted

semi-elliptical spring for each of the front and rear

axles, which was a solid beam axle, not an independent

suspension, which still allowed a great deal of wheel

movement to cope with the dirt roads of the time.

The front axle was drop forged

as a single piece of vanadium steel. Ford twisted many

axles eight times and sent them to dealers to be put on

display to demonstrate its superiority. The Model T did

not have a modern service brake. The right foot pedal

applied a band around a drum in the transmission, thus

stopping the rear wheels from turning. The previously

mentioned parking brake lever operated band brakes on

the outside of the rear brake drums.

Wheels were wooden artillery

wheels, with steel welded-spoke wheels available in 1926

and 1927.

Tires were pneumatic clincher

type, 30 in (76 cm) in diameter, 3.5 in (8.9 cm) wide in

the rear, 3 in (7.5 cm) wide in the front. Clinchers

needed much higher pressure than today's tires,

typically 60 psi (410 kPa), to prevent them from leaving

the rim at speed. Horseshoe nails on the roads, together

with the high pressure, made flat tires a common

problem.

Balloon tires became available

in 1925. They were 21 Χ 4.5 in (53 Χ 11 cm) all around.

Balloon tires were closer in design to today's tires,

with steel wires reinforcing the tire bead, making lower

pressure possible typically 35 psi (240 kPa) giving

a softer ride. The old nomenclature for tire size

changed from measuring the outer diameter to measuring

the rim diameter so 21 in (530 mm) (rim diameter) Χ

4.5 in (110 mm) (tire width) wheels has about the same

outer diameter as 30 in (76 cm) clincher tires. All

tires in this time period used an inner tube to hold the

pressurized air; "tubeless" tires were not generally in

use until much later.

Wheelbase was 99 inches

(250 cm); while standard tread width was 56 in (142 cm),

60 in (152 cm) tread could be obtained on special order,

"for Southern roads".

Design changes

Up until 1916, early Ts had a

brass radiator and headlights. The horn and numerous

small parts were also brass. Many of the early cars were

open-bodied touring cars and runabouts, these being

cheaper to make than closed cars. Prior to the 1911

model year (when front doors were added to the touring

model), US - made open cars did not have an opening door

for the driver. Later models included closed cars

(introduced in 1915), sedans, coupes and trucks. The

chassis was available so trucks could be built to suit.

Ford also developed some truck bodies for this chassis,

designated the Model TT. The headlights were originally

acetylene lamps made of brass (commonly using

Prest-O-Lite tanks), but eventually the car gained

electric lights after 1910, initially powered from the

magneto until the electrical system was upgraded to a

battery, generator and starter motor, when lighting

power was switched to the battery source.

The Model T production system,

the epitome of Fordism, is famous for representing the

rigidity of early mass production systems that were

wildly successful at achieving efficiency but that could

accommodate changes in product design only with great

difficulty and resistance. The story is more

complicated; there were few major, publicly visible

changes throughout the life of the model, but there were

many smaller changes. Most were driven by design for

manufacturability considerations, but styling and new

features also played more of a role than commonly

realized. In fact, one of the problems for the company

regarding design changes was the T's reputation for not

changing and being "already correct", which Henry Ford

enjoyed and which was a selling point for many

customers, which made it risky to admit any changes

actually were happening. (The idea of simply refining a

design without making radical visible changes would

resurface, and score even greater production success,

with the VW Type 1.)

Cylinder Head Changes

|

Date of Change |

Factory Number |

Change |

|

12-11-08 |

T401BR |

Adopte1d |

|

12-29-08 |

T401BR |

Changed screw hole

from 25/64 to 29/64&q2ot; |

|

03-23-09 |

T401BR |

Added for use after 1st 250

cars |

|

12-06-20 |

T401BR |

Obsolete - "all stock

scrapped in June" |

|

02-01-09 |

T401C |

Adopted

(Thermo-syphon) |

|

02-14-10 |

T401C |

Removed spotting boss

from rear end |

|

03-14-11 |

T401C |

Increased compression

space by 3/32" |

|

07-22-11 |

T401C |

Added spotting boss to

rear end |

|

04-16-12 |

T401C |

Added "Made in U.S.A." |

|

06-10-12 |

T401C |

Added bosses between

combustion chamber and water jacket for 1/8"

pipe taps on left side of head. |

|

11-26-12 |

T401C |

Removed 1/8" pipe taps

for priming. Bosses remain. |

|

07-17-14 |

T401C |

Added 3/32 to bottom

of head, increases all top to bottom

dimensions and lowers compression. |

|

05-17-17 |

T401C |

Redesigned High Head

Changes ASAP, Use Up Old Stock. |

|

08-15-17 |

T401C |

Added 3/4" cored hole

between chambers 2 & 3. |

|

02-23-18 |

T401C |

Changed rear locating

boss from 5/8" square to 1/2" |

|

09-25-18 |

T401C |

Reduced height of

combustion chamber 1/16" |

|

01-12-20 |

T401C |

Removed rear locating

boss |

|

05-18-26 |

T401C |

Reduced height of

combustion chamber 3/32" |

|

06-22-26 |

T401C |

Increased height of

combustion chamber 3/32". |

|

10-20-26 |

T401C |

Specified paint with

M-124 |

Colors

By 1918, half of all the cars

in the US were Model T's. However it was a monolithic

bloc; Ford wrote in his autobiography that he told his

management team in 1909 that in the future

"Any

customer can have a car painted any color that he wants

so long as it is black".

However, in the first years of

production from 1908 to 1914, the Model T was not

available in black but rather only grey, green, blue,

and red. Green was available for the touring cars, town

cars, coupes, and Landaulets. Grey was only available

for the town cars, and red only for the touring cars. By

1912, all cars were being painted midnight blue with

black fenders. It was only in 1914 that the "any color

as long as it is black" policy was finally implemented.

It is often stated that Ford suggested the use of black

from 1914 to 1926 due to the cheap cost and durability

of black paint. During the lifetime production of the

Model T, over 30 different types of black paint were

used on various parts of the car. These were formulated

to satisfy the different means of applying the paint to

the various parts, and had distinct drying times,

depending on the part, paint, and method of drying.

Diverse applications in a world not

yet widely paved, motorized, or

electrified

Read full article

Read full article

here.

here.

When the Model T was designed

and introduced, the infrastructure of the world was

quite different from today's. Pavement was a rarity

except for sidewalks and a few big-city streets. (The

sense of the term "pavement" as equivalent with

"sidewalk" comes from that era, when streets and roads

were generally dirt (mud during rainy periods) and

sidewalks were a paved way to walk down them without

getting dirty. In fact, this was a motive for

segregating foot traffic from carriage traffic long

before the speed of automobiles provided another

motive.) Agriculture was the occupation of many people.

Power tools were scarce outside factories, as were any

power sources to run them; electrification, like

pavement, was found usually only in larger towns and

cities. Rural electrification and motorized

mechanization were embryonic in North America and

Europe, and nonexistent elsewhere.

Henry Ford oversaw the

requirements and design of the Model T based on the

realities of that world. Consequently, the Model T was

(intentionally) almost as much a tractor and stationary

engine as it was an automobile, that is, a vehicle

dedicated solely to road use. It has always been well

regarded for its all-terrain abilities and ruggedness.

It could travel a rocky, muddy farm lane, ford a shallow

stream, climb a steep hill, and be parked on the other

side to have one of its wheels removed and a pulley

fastened to the hub for a flat belt to drive a bucksaw,

thresher, silo blower, conveyor for filling corn cribs

or haylofts, baler, water pump (for wells, mines, or

swampy farm fields), electrical generator, and countless

other applications. One unique application of the Model

T was shown in the October 1922 issue of Fordson Farmer

magazine. It showed a minister who had transformed his

Model T in to a mobile church, complete with small

organ.

During this era, entire

automobiles (including thousands of Model Ts) were even

hacked apart by their industrious owners and

reconfigured into custom machinery permanently dedicated

to a purpose, such as homemade tractors, ice saws, or

many others. Dozens of aftermarket companies sold prefab

kits to facilitate the T's conversion from car to

tractor. In a world mostly without mechanized

cultivators, Model Ts filled a vacuum. Row-crop tractors

such as the Farmall did not become widespread until the

1930s. Like many popular car engines of the era, the

Model T engine was also used on home-built aircraft

(such as the Pietenpol Sky Scout) and motorboats.

Also, many Model Ts were

converted into vehicles which could travel across heavy

snows with kits on the rear wheels and skis where the

front wheels were located. They were popular for rural

mail delivery for a time. The common name for these

conversions of cars and small trucks was Snowflyers.

These vehicles were extremely popular in the northern

reaches of Canada where factories were set up to produce

them.

Production

Mass production

The knowledge and skills needed

by a factory worker were reduced to 84 areas. When

introduced, the T used the building methods typical at

the time, assembly by hand, and production was small.

Ford's Piquette plant could not keep up with demand for

the Model T, and only 11 cars were built there during

the first full month of production. More and more

machines were used to reduce the complexity within the

84 defined areas. In 1910, after assembling nearly

12,000 Model Ts, Henry Ford moved the company to the new

Highland Park complex.

As

a result, Ford's cars came off the line in three-minute

intervals, much faster than previous methods, reducing

production time by a factor of eight (requiring 12.5

hours before, 93 minutes afterwards), while using less

manpower. By 1914, the assembly process for the Model T

had been so streamlined it took only 93 minutes to

assemble a car. That year Ford produced more cars than

all other automakers combined. The Model T was a great

commercial success, and by the time Henry made his 10

millionth car, 50 percent of all cars in the world were

Fords. It was so successful that Ford did not purchase

any advertising between 1917 and 1923; more than

15 million Model Ts were manufactured, reaching a rate

of 9,000 to 10,000 cars a day in 1925, or 2 million

annually, more than any other model of its day, at a

price of just $240. Model T production was finally

surpassed by the Volkswagen Beetle on February 17, 1972. As

a result, Ford's cars came off the line in three-minute

intervals, much faster than previous methods, reducing

production time by a factor of eight (requiring 12.5

hours before, 93 minutes afterwards), while using less

manpower. By 1914, the assembly process for the Model T

had been so streamlined it took only 93 minutes to

assemble a car. That year Ford produced more cars than

all other automakers combined. The Model T was a great

commercial success, and by the time Henry made his 10

millionth car, 50 percent of all cars in the world were

Fords. It was so successful that Ford did not purchase

any advertising between 1917 and 1923; more than

15 million Model Ts were manufactured, reaching a rate

of 9,000 to 10,000 cars a day in 1925, or 2 million

annually, more than any other model of its day, at a

price of just $240. Model T production was finally

surpassed by the Volkswagen Beetle on February 17, 1972.

Henry Ford's ideological

approach to Model T design was one of getting it right

and then keeping it the same; he believed the Model T

was all the car a person would, or could, ever need. As

other companies offered comfort and styling advantages,

at competitive prices, the Model T lost market share.

Design changes were not as few as the public perceived,

but the idea of an unchanging model was kept intact.

Eventually, on May 26, 1927, Ford Motor Company ceased

production and began the changeovers required to produce

the Model A.

Model T engines continued to be

produced until August 4, 1941. Almost 170,000 were built

after car production stopped, as replacement engines

were required to service already produced vehicles.

Racers and enthusiasts, forerunners of modern hot

rodders, used the Model T's block to build popular and

cheap racing engines, including Cragar, Navarro, and

famously the Frontenacs ("Fronty Fords") of the

Chevrolet brothers, among many others.

The Model T employed some

advanced technology, for example, its use of vanadium

steel alloy. Its durability was phenomenal, and many

Model Ts and their parts remain in running order nearly

a century later. Although Henry Ford resisted some kinds

of change, he always championed the advancement of

materials engineering, and often mechanical engineering

and industrial engineering.

In 2002, Ford built a final

batch of six Model Ts as part of their 2003 centenary

celebrations. These cars were assembled from remaining

new components and other parts produced from the

original drawings. The last of the six was used for

publicity purposes in the UK.

Although Ford no longer

manufacture parts for the Model T, many parts are still

manufactured through private companies as replicas to

service the thousands of Model T's still in operation

today.

Price

The standard 4-seat open tourer

of 1909 cost $850 (equivalent to $20,709 today), when

competing cars often cost $2,000$3,000 (equivalent to

$48,726$73,089 today); in 1913, the price dropped to

$550 (equivalent to $12,181 today), and $440 in 1915

(equivalent to $9,521 today). Sales were 69,762 in 1911;

170,211 in 1912; 202,667 in 1913; 308,162 in 1914; and

501,462 in 1915. In 1914, an assembly line worker could

buy a Model T with four months' pay.

By the 1920s, the price had

fallen to $290 (equivalent to $3,289 today) because of

increasing efficiencies of assembly line technique and

volume. Henry employed vertical integration of the

industries needed to create his cars.

View

full price list from 1909 to 1927

here, with some

interesting inflation-adjusted figures. View

full price list from 1909 to 1927

here, with some

interesting inflation-adjusted figures.

Recycling

Henry Ford used wood scraps

from the production of Model T's to create charcoal.

Originally named Ford Charcoal the name was changed to

Kingsford Charcoal

after Ford's relative E. G. Kingsford brokered the

selection of the new charcoal plant site.

First global car

The Ford Model T was the first

automobile built by various countries simultaneously

since they were being produced in Walkerville, Canada

and in Trafford Park, Greater Manchester, England

starting in 1911 and were later assembled in Germany,

Argentina, France, Spain, Denmark, Norway, Belgium,

Brazil, Mexico, and Japan. Ford made use of the

knock-down kit concept almost from the beginning of the

company.

The Aeroford was an English

automobile manufactured in Bayswater, London, from 1920

to 1925. It was a Model T with distinct hood and grille

to make it appear to be a totally different design, what

later would have been called badge engineering. The

Aeroford sold from £288 in 1920, dropping to £168-214 by

1925. It was available as a two-seater, four-seater, or

coupι.

Advertising, marketing, and

packaging

Ford created a massive

publicity machine in Detroit to ensure every newspaper

carried stories and advertisements about the new

product. Ford's network of local dealers made the car

ubiquitous in virtually every city in North America. As

independent dealers, the franchises grew rich and

publicized not just the Ford but the very concept of

automobiling; local motor clubs sprang up to help new

drivers and to explore the countryside. Ford was always

eager to sell to farmers, who looked on the vehicle as a

commercial device to help their business. Sales

skyrocketed several years posted 100% gains on the

previous year.

Sales passed 250,000 in 1914. By 1916, as the price

dropped to $360 for the basic touring car, sales reached

472,000.

Car clubs

Cars built before 1919 are classed as veteran cars and

later models as vintage cars. Today, four main clubs

exist to support the preservation and restoration of

these cars: The Model T Ford Club International, the

Model T Ford Club of America and the combined clubs of

Australia.

With many chapters of clubs

around the world, the Model T Ford Club of Victoria has

a membership with a considerable number of uniquely

Australian cars. (Australia produced its own car bodies

and therefore many differences occurred between the

Australian bodied tourers and the US/Canadian cars). In

the UK, the Model T Ford Register of Great Britain

celebrated its 50th anniversary in 2010.

Many steel Model T parts are

still manufactured today, and even fiberglass replicas

of their distinctive bodies are produced, which are

popular for T-bucket style hot rods (as immortalized in

the Jan and Dean surf music song "Bucket T," which was

later recorded by The Who).

In 2008, there was an around

Australia trip organised by various members of the NSW

portion of the Combined model T clubs of Australia.

Along the trip the members of the club met the likes of

Malcolm Douglas and others. The trip lasted just over 6

months, all of this time the members ate, drank and

slept in their cars that they had modified for the trip.

They left Sydney on 20th, April and made it all the way

to Echuca in Victoria for the 100 year anniversary of

the Model T Ford. People come from all over Australia,

New Zealand and America for the trip to one major city

in Australia that is held every 3 years, they stayed for

a week in Echuca and participated in various activities

organised by the Victoria club and eventually moved on

to go home and see their families back in Sydney on the

9th, October 2008.

In The Music Man by Meredith Wilson Model

T's are blamed for changes in society and the life of

travelling salesmen. "Why it's the Model T Ford made the

trouble, made the people/ Want to go, want to git, want

to git, want to git up and go/ Seven, eight, nine, ten,

twelve, fourteen, twenty-two, twenty-three miles to the

county seat/ Yes Sir Yes Sir/ Who's gonna patronize a

little bitty two-by-four kind of store any more?"

The End of the Model T's Reign

On

June 4, 1924, the ten millionth Model T Ford left the

Highland Park factory, which would remain the main facility for

T production. While the flivver outsold its nearest competitor

by a six-to-one margin that year, its unbridled run was nearing

an unforeseen conclusion. After years of conceding the low end

of the market to Ford, another automaker was setting its sights

on that very sector. On

June 4, 1924, the ten millionth Model T Ford left the

Highland Park factory, which would remain the main facility for

T production. While the flivver outsold its nearest competitor

by a six-to-one margin that year, its unbridled run was nearing

an unforeseen conclusion. After years of conceding the low end

of the market to Ford, another automaker was setting its sights

on that very sector.

At the beginning of the decade,

General Motors was an awkward conglomerate of car

companies and parts suppliers, managed more for the sake

of its whipsaw stock-price than for efficiencies in auto

making. In the middle of the decade, though, a

revitalized GM, under the brilliant leadership of Alfred

P. Sloan, Jr., began to offer inexpensive Chevrolets

with amenities that the Model T lacked. Instead of the

sturdy but antiquated planetary transmission, it had a

smooth three-speed. The market began to shift; price and

value ceased to be paramount factors. Styling and

excitement suddenly counted to the customer. Even though

the Model T cost a mere $290 in the mid-twenties,

dealers clamored for a new Ford that would strike the

fancy of the more demanding and sophisticated consumers.

But Henry Ford refused even to consider replacing his

beloved Model T. Once, while he was away on vacation,

employees built an updated Model T and surprised him

with it on his return. Ford responded by kicking in the

windshield and stomping on the roof. "We got the

message," one of the employees said later, "As far as he

was concerned, the Model T was god and we were to put

away false images." Only one person persisted in warning

him of the impending crisis: his son, Edsel, who had

been installed as president of the Ford Motor Company

during the dividend trial and its aftermath in 1919. It

was the first of many arguments that Edsel would lose,

as the once adoring relationship between the two

deteriorated into distrust and disrespect on Henry's

part and woeful disillusionment on Edsel's.

The Chevrolet continued to take sales from the dour

Model T. By 1926, T sales had plummeted, and the

realities of the marketplace finally convinced Henry

Ford that the end was at hand.

On

May 25, 1927, Ford abruptly announced the end of

production for the Model T, and soon after closed the

Highland Park factory for six months. The shutdown was

not for retooling: there was no new model in the works.

In history's worst case of product planning, Henry sent

the workers home so that he could start to design his

next model. Fortunately, Edsel had been quietly

marshalling sketches from the company's designers, and

he was ready and able to work with his father on

producing plans for the new car, called the Model A. It

was a success from its launch in December 1927, and

placed the company on sound footing again. By the time

it went into production, the River Rouge had become the

main Ford manufacturing facility. On

May 25, 1927, Ford abruptly announced the end of

production for the Model T, and soon after closed the

Highland Park factory for six months. The shutdown was

not for retooling: there was no new model in the works.

In history's worst case of product planning, Henry sent

the workers home so that he could start to design his

next model. Fortunately, Edsel had been quietly

marshalling sketches from the company's designers, and

he was ready and able to work with his father on

producing plans for the new car, called the Model A. It

was a success from its launch in December 1927, and

placed the company on sound footing again. By the time

it went into production, the River Rouge had become the

main Ford manufacturing facility.

When the last Model T rolled off the assembly line, it

was not the end of an era, it was still the very dawn of

the one that the little car had inaugurated. Cars --

more than half of them Model Ts -- pervaded American

culture. They jammed the streets of the great eastern

cities and roamed newly laid roads in southern

California. Adapted to haul everything from mail to

machine guns to coffins to schoolchildren, automobiles

represented an opportunity for change in practically

everything. They also became a crucial factor in

recasting a growing economy. Henry Ford had created a

car for the multitudes and that car had created the

basis of the car culture embraced by every subsequent

generation.

The Ford Motor Company, having survived its own crisis

in the twenties, was one of only forty-four U.S.

automakers left in 1929, out of the hundreds that had

entered the fray since the beginning of the century.

That year, Ford, General Motors, and the newly formed

Chrysler Corporation -- known then and now as the Big

Three -- accounted for 80 percent of the market.

Henry Ford died on April 7, 1947, at the age of

eighty-three, having outlived the Model T by nearly

twenty years. A century has passed since he took the

first car he built for a ride. The world remains in

large part the one set into motion by Henry Ford: a

world in which cars are for everyone. As Will Rogers

said, "It will take a hundred years to tell whether he

helped us or hurt us, but he certainly didn't leave us

where he found us."

Model T Fast Facts

|

The Model T was introduced

on Oct. 1, 1908. It had a 20-horsepower,

four-cylinder engine, reached a top speed of

about 45 miles per hour, got about 13 to 21

miles per gallon of gasoline and weighed 1,200

pounds. It was the ninth of Henry Ford's

production cars. |

|

More than 15,000,000 Model

T's were built and sold. A modest ceremony on

May 26, 1927, marked the formal end of Model T

production. |

|

The first models were

produced at a factory on Piquette Avenue in

Detroit. Beginning in 1910, Model T's were built

at a new Highland Park (Michigan) plant. |

|

Henry Ford's initiation of

mass production of vehicles on the moving

assembly line led to lower car prices and the $5

workday. |

|

The car was introduced

with a price tag of $850. The Model T later sold

for as little as $260, without extras, because

of production savings Henry Ford passed on to

customers. |

|

Henry Ford called the

Model T "the universal car," a low-cost,

reliable vehicle that could be maintained easily

and could successfully travel the poor roads of

the era. |

|

The Model T came in nine

body styles, all on the same chassis. |

|

"Lizzie" was one of the

most popular of the dozens of nicknames for the

Model T. |

|

In 1914, Ford, with 13,000

employees, produced about 300,000 cars while 299

other companies with 66,350 employees produced

about 280,000 vehicles. |

-

John Steele Gordon "10 Moments That Made

American Business," American Heritage,

February/March 2007.

-

Ford also attempted a buy on time

program to aid sales, resembling that of

the German Kdf-Wagen (forerunner of the

Volkswagen Type 1). Ford's plan was not

a success, either.

-

"Joyrides: Car of the Century/ Ford's

Model T, of course".

-

"Chronicle of 1908".

Library.thinkquest.org. Retrieved

2010-11-15.

-

"Henry Ford And The Model T". John Wiley

& Sons. Retrieved February 3, 2011.

-

Early Ford models from the years

19031908; p. 5.

-

Ford 1922,

My life and work (1922), p. 73.

-

Lacey 1986.

-

Reynolds 2009

-

"University students compete to create

21st century Model T". Media.ford.com.

Retrieved January 17, 2011.

-

"History Lesson: Hungary Celebrates the

Ford Model T." Fadaweb.com. Retrieved

2012-01-01

-

Wik 1972.

-

a

b Clymer 1950,

p. 100.

-

"Model T Facts". Media.ford.com

accessdate=November 15, 2010.

-

English, Andrew (July 25, 2008). "Ford

Model T reaches 100". The Telegraph.

Retrieved August 8, 2008.

-

"Ethanol: Introduction". Journey to

Forever. Retrieved August 8, 2008.

-

"Model T Ford Electrical System".

modeltcentral.com. Retrieved October 15,

2009.

-

1926 "Model T Ford Club of America".

-

Clymer 1950, p. 37.

-

Hounshell 1984, pp. 273278.

|

-

Hounshell 1984, p. 275.

-

It would also apply to the Porsche 911.

-

Ford 1922, p. 72.

-

Model T: The car that changed the

world)

-

McCalley 1994

-

Casey, Robert (2008). The Model T A

Centennial History. Baltimore: The

Johns Hopkins University Press. pp. 148.

ISBN 978-0-8018-8850-2.

-

"1926 Ford Model T Ice Saw". Used for

harvesting winter ice from ponds in

Maine.

-

Pripps & Morland 1993, p. 28

-

"Snowflyers Replace Dogs in Frozen

North" Popular Mechanics,

December 1934

-

a

b c

Georgano 1985

-

Martin W. Sandler, Driving Around the

USA: Automobiles in American Life,

Oxford University Press, 2003, p.21

-

Douglas Brinkley, Wheels for the world:

Henry Ford, his company, and a century

of progress, 19032003, Viking, 2003,

p.475

-

My forty years with Ford, Charles E.

Sorensen, David Lanier Lewis, Samuel T.

Williamson, Wayne State University

Press, p.4

-

detnews.com "Michigan History".

-

Ward 1974, p. 1562.

-

History

Page Kingsford products[dead

link]

-

www.auto-historia.com History of Ford

Motors Argentina Retrieved on 19

November 2008.

-

Celebrating the Ford Model T, only 100

years young!, (in Spanish) accessed 22

September 2008.

-

David Culshaw & Peter Horrobin: The

Complete Catalogue of British Cars

18951975. Veloce Publishing plc.

Dorchester (1999). ISBN 1-874105-93-6

-

Lewis 1976, pp. 4159.

|

|